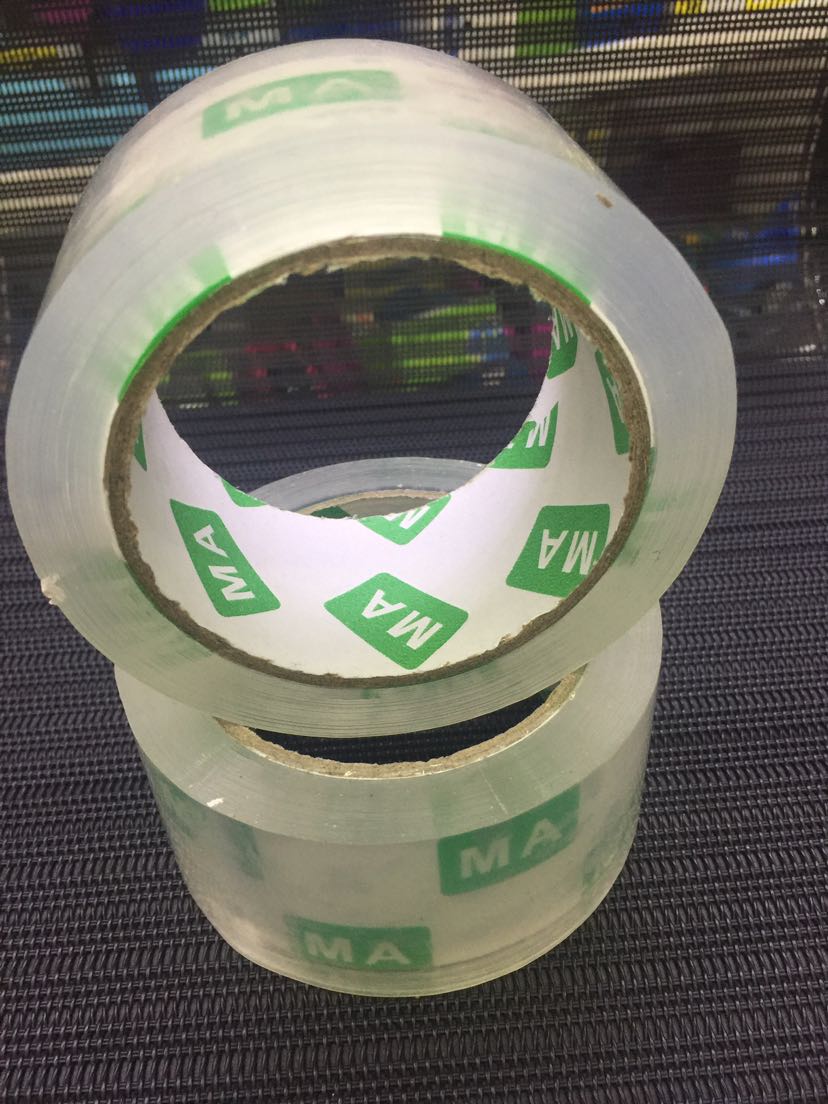

Solving packaging problems: high-stick transparent factory sealing tape

In the rapidly developing market environment, efficient packaging materials have become one of the important challenges facing factories and express delivery industries. How to improve packaging speed and safety and reduce costs while ensuring product quality has become an urgent problem for many companies. It is in this context that high-viscosity transparent factory sealing tape came into being and became the first choice for many enterprises.

With its excellent performance, this tape can not only greatly improve work efficiency, but also effectively reduce packaging costs. Especially in the express delivery industry, it provides a solid guarantee for the safe transportation of packages with its excellent sealing ability and tear resistance.

Superior Performance: Why High Tack Transparent Sealing Tape

The reason why high-viscosity transparent factory sealing tape is favored by the market is mainly due to its several core advantages:

- Super adhesion: Even when facing a rough or porous surface, it can form a strong adhesion to ensure that the package reaches its destination safely.

- Excellent weather resistance: It can maintain stable performance under extreme weather conditions without being affected by temperature and humidity.

- Good operation convenience: Easy to peel off without leaving residual glue, and complete the packaging process conveniently and quickly.

These features make the high-viscosity transparent factory sealing tape perform well in various environments and have won high recognition from users.

Wide range of applications: not just express

Although the high-viscosity transparent factory sealing tape was originally tailored for the express delivery industry, its wide applicability and superior performance have quickly expanded to many other fields. For example, in the manufacturing industry, it is used for temporary fixation and protection of machinery and equipment; in warehousing and logistics, it is used as the preferred material for packing goods; even in home decoration, it is often used to seal boxes or protect walls from scratches.

Whether in the industrial production line or in daily life, the high-viscosity transparent factory sealing tape has shown extremely high practical value and has become an indispensable good helper.

How do I choose the right specification?

In order to better meet the diverse needs of different users, high-viscosity transparent factory sealing tape provides a variety of specifications to choose from. When selecting, you can consider the following factors:

- Item size: Larger items usually require wider tape to achieve a better sealing effect.

- Item weight: For heavier items, it is recommended to choose a model with stronger adhesion to ensure safe transportation.

- Operating environment: If the working environment is harsh, such as high temperature, humidity, etc., you need to choose a tape with good weather resistance.

By considering the above points, you can more easily find the most suitable for your needs of high-stick transparent factory sealing tape specifications.

Tips: Maximize Tape Performance

In order to give full play to the effectiveness of high-viscosity transparent factory sealing tape, here are some tips for reference:

- Surface cleaning: Before use, please ensure that the bonded surface is clean and dry, which will help improve the adhesion.

- Correct pressure: Apply a certain amount of pressure when applying the tape, which can make the tape closely integrate with the surface of the object and enhance the sealing effect.

- reasonable cutting: cut the appropriate length according to the actual situation, neither too long nor too short, which can save materials and facilitate operation.

Maintenance and storage: extended service life

Proper maintenance and storage methods are essential to keep the high-viscosity transparent factory sealing tape in good condition. First, it should be stored in a cool and dry place